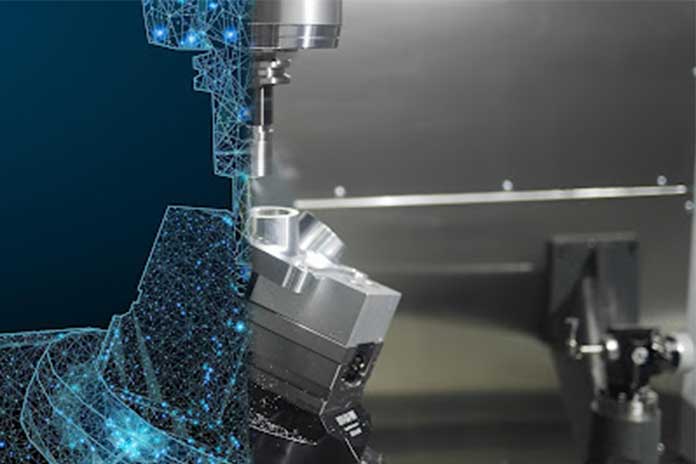

Computer numerical control (CNC) technology is a popular option in the manufacturing industry today. This is because it offers valuable benefits such as precision, consistent quality and speed of production. However, in order to take advantage of these many benefits, you must first find the right provider for your CNC work. Here are the different possibilities in this context.

Online platforms for CNC work

The first way to find providers of CNC work is to use specialized platforms. Indeed, there are many intermediation sites between customers and providers of parts manufacturing services. In other words, these platforms allow you to publish your projects and receive offers from qualified professionals.

The benefits of using this alternative are multiple. They include convenience, speed, ease of use, competitive pricing and a wide variety of providers. It should be noted that you can request for cnc machining online quote to compare offers.

However, the quality of the machining can vary depending on the online platforms. The providers are precisely located in different parts of the world, which leads to differences in standards. Therefore, it is up to customers to look beyond price and seek proof of reliability before hiring a provider.

Also Read: Understand What Technology Has To Offer Your Business

General engineering companies

General engineering companies are also a solution for providing CNC services. These companies usually have expertise in various types of manufacturing processes, including CNC. They can even offer options for taking over the equipment needed for the work.

There are obviously benefits to working with these general mechanical companies. These include:

- Geographical proximity,

- Flexibility in volume orders,

- The ability to provide a wider range of services, etc.

However, this alternative also has its limitations. There are some general engineering companies offering CNC services that are not specialized in the field. This inevitably leads to process errors or quality problems. It is therefore advisable to check whether the company has the expertise it claims before hiring it.

Specialized machine shops

Finally, specialized machine shops also offer CNC services. They are equipped with state-of-the-art CNC machine tools that allow them to produce parts with precision and surface quality. They can work with a wide variety of materials, such as metals, plastics, composites, ceramics, etc.

These workshops handle projects of all sizes, from prototyping to mass production. They help their customers design parts and optimize their manufacturing processes to reduce costs and lead times. Their sectors of intervention include aeronautics, automotive, energy, electronics, medical, space, etc.

Specialized workshops frequently maintain and test their machines using digital dial indicators and digital oscilloscopes to ensure the final product meets your expectations.

In addition, specialized machine shops offer complementary services such as heat treatment, surface treatment, assembly, marking and finishing. The advantages of such a wide range of skills are numerous. These include personalization, quality, confidentiality and fluidity of communication. By working directly with people, clients can better expose technical details to avoid misunderstandings.

However, one significant limitation emerges from all of these opportunities. Specialized machine shops have higher costs than all other CNC work options. For those looking for affordable solutions, online platforms are proving more attractive. You need to know how to select the best ones to get a quality service.

Also Read: Eight Benefits Of Technology For Companies